Extraction process

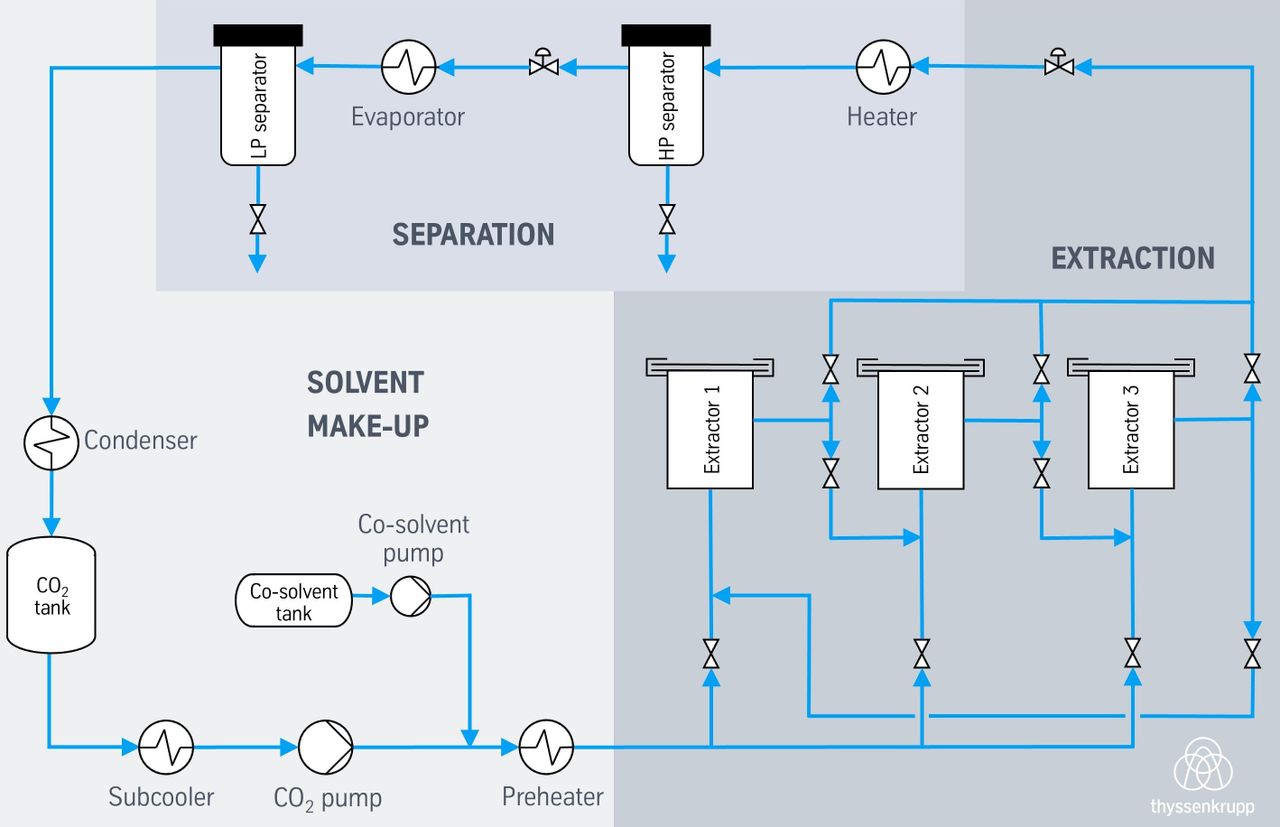

The extraction process using supercritical CO2 consists of the following three major process steps:

Solvent make-up (recovery, storage of solvent, pressurization,…)

Extraction

Separation of extract from solvent (CO2)

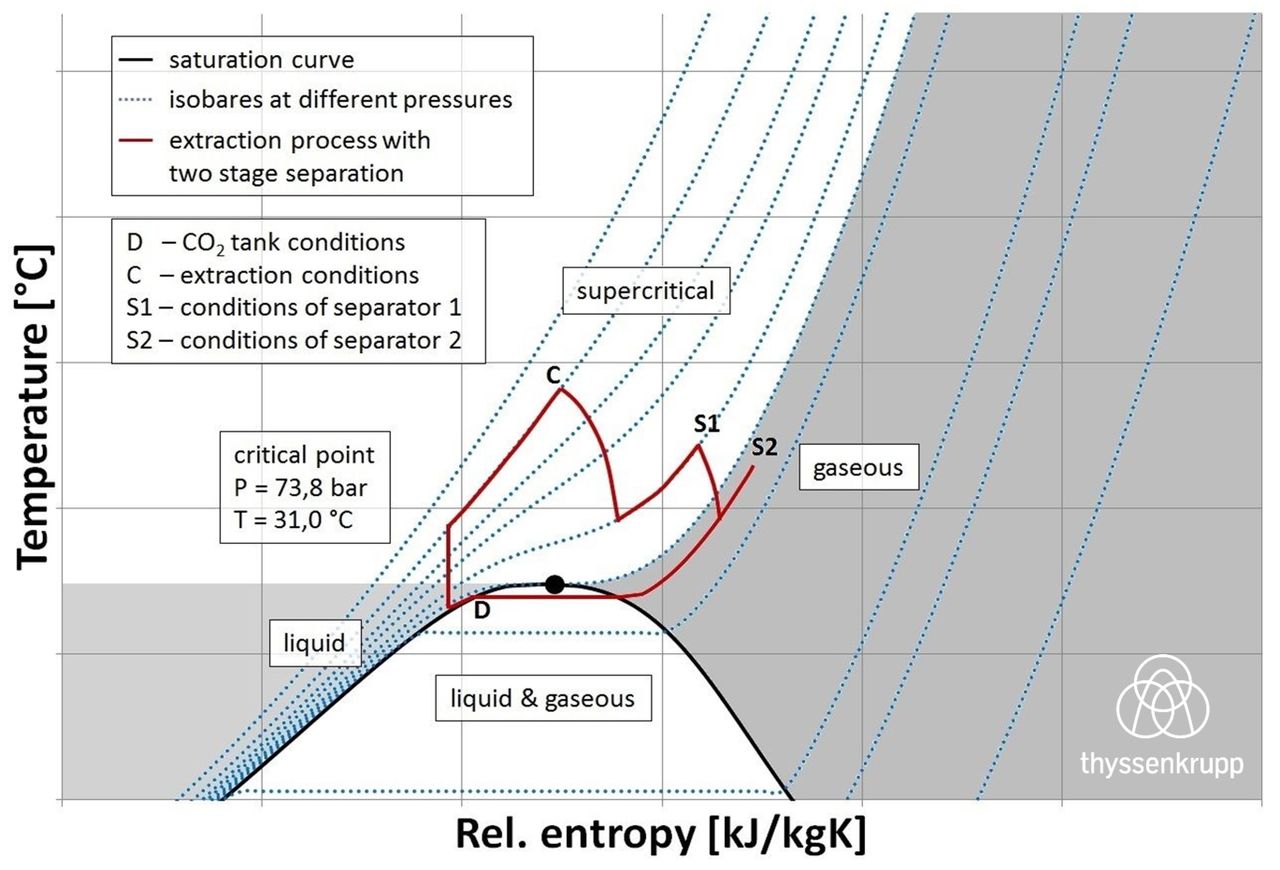

Within the solvent make-up step the CO2 is recycled, stored and conditioned to match the process specifications. If recycling of the CO2 is considered, the amount of CO2 needed to pressurize the plant is stored in a buffer tank. There the CO2 is stored at its vapor-liquid equilibrium at around 60 bar and 22°C.

During the first step of the process the CO2 is cooled down before going to the CO2 pump which pressurizes the CO2 to extraction pressure. Cooling the CO2 before entering the CO2 pump prevents possible cavitation inside the pump. After the pressurization, the CO2 is pre-heated to the desired extraction temperature before entering the active extractor. Inside the extractor vessel there is usually a basket, charged with the product to facilitate the product exchange. The CO2 flows through the basket and thus the product material. The solubility of certain feed compounds in the CO2 causes these (organic) components to dissolve in the CO2. The CO2 loaded with those extracts is transported to the depressurization valve which controls the pressure inside the extractor. After the depressurization of the loaded CO2 it is routed through a pre-heater to reach the desired separation temperature and is introduced into the separator. Since the solubility of the extract in the CO2 is strongly dependent on pressure and temperature, the extract is separated inside the separator. Depending on the product, additional separation steps can be realized allowing a fractionation of the extract by using different pressure stages and temperatures. After leaving the separators the CO2 can be recovered to the buffer tank using a condenser to liquefy the (partially) gaseous CO2 thus optimizing the loss of solvent.

Supercritical fluids extraction process explained

Supercritical fluids are a powerful all-rounder when it comes to extraction of natural organic substances. Mild process temperatures, a non-toxic solvent and easy separation of extracts and solvent ensure high-quality products with high purities. Watch this video explaining how the extraction process works and how supercritical fluids are utilized.

/thyssenkrupp_logo_claim_d.svg)