High Pressure Processing (HPP)

High pressure processing (HPP)

Simply fresh and safe – high pressure preservation at 6,000 bar

Consumers want natural, fresh products – ideally without additives and without the loss of nutrients caused by heating. At the same time, around 30% of food is still being thrown away, some of it before even being sold. High pressure processing by thyssenkrupp allows gentle preservation of food by high pressure – without additives or heat. The latter is an important difference to "classic" thermal pasteurization, even though HPP is also known as "high-pressure pasteurization". Products are processed in their packaging. It works for vacuum and modified atmosphere packs and for plastic bottles. The result: much longer shelf life and maximum product safety and therefore more satisfied customers. At the same time the texture, look, nutrients and taste of your products remain intact. And all of that is achieved while HPP being environment-friendly and free of waste.

How does HPP work? Water and pressure. Nothing else.

All the HPP process needs is water (which can be recirculated) and power for the pumps. By using pressure for the preservation of foods and beverages neither heat nor any chemicals are required. Products are typically cooled before entering the HPP process. Pressurization increases the temperature by around 18°C and the products are compressed by around 16% in their packaging. During decompression the product cools roughly back to its initial temperature and expands back to its original size. As high temperatures are not needed the products remain fresh and flavorful and won’t undergo unintended changes in color or structure as if thermal heat would be applied. This makes high pressure processing or high hydrostatic pressure processing (HHP) as it can be called as well the natural choice for high quality.

Here we answer further questions about High Pressure Processing: What is HPP?

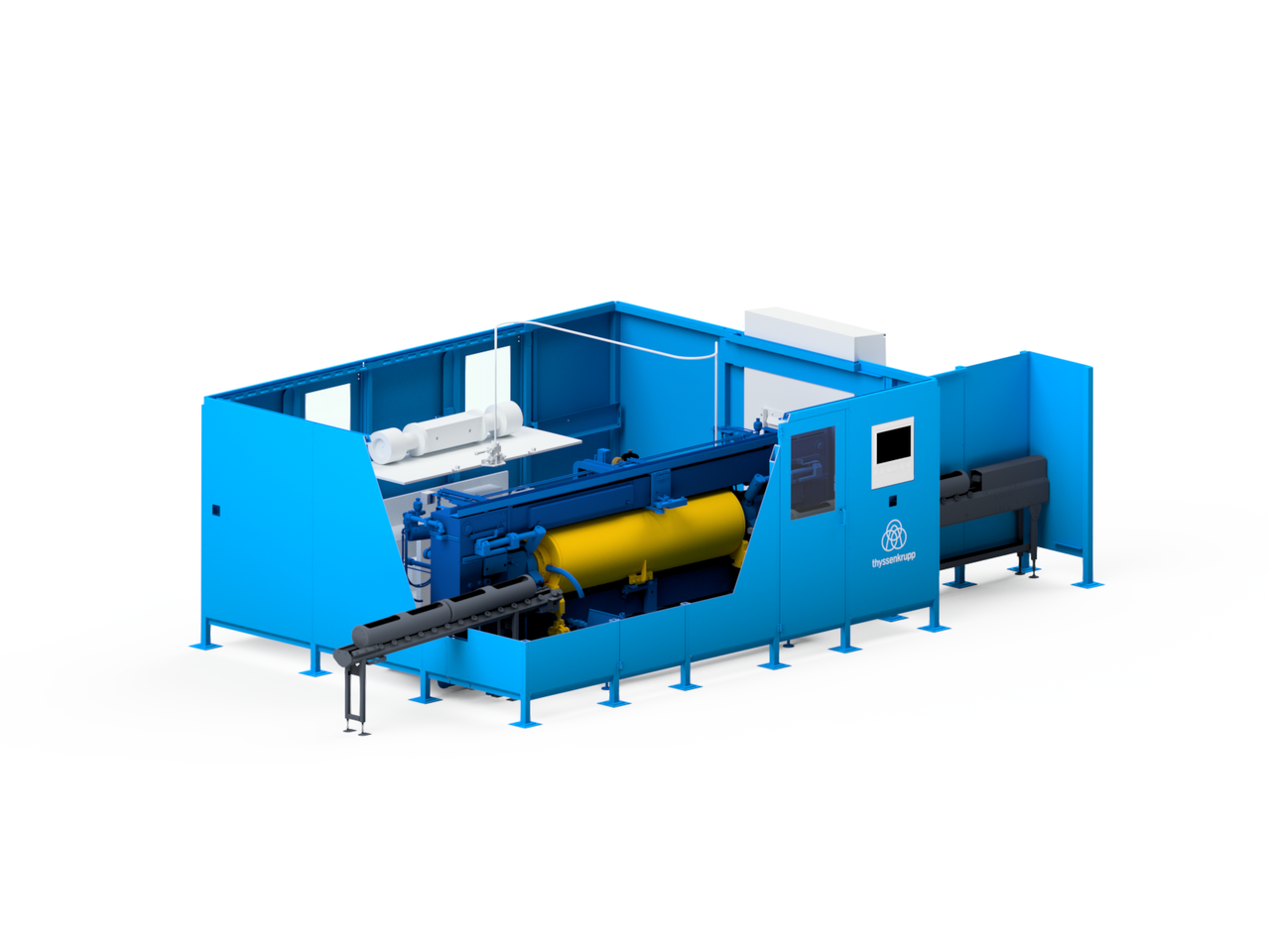

NEW: Uhde 400L+ HPP Plant

Explore our HPP machine

Our HPP plants and machines

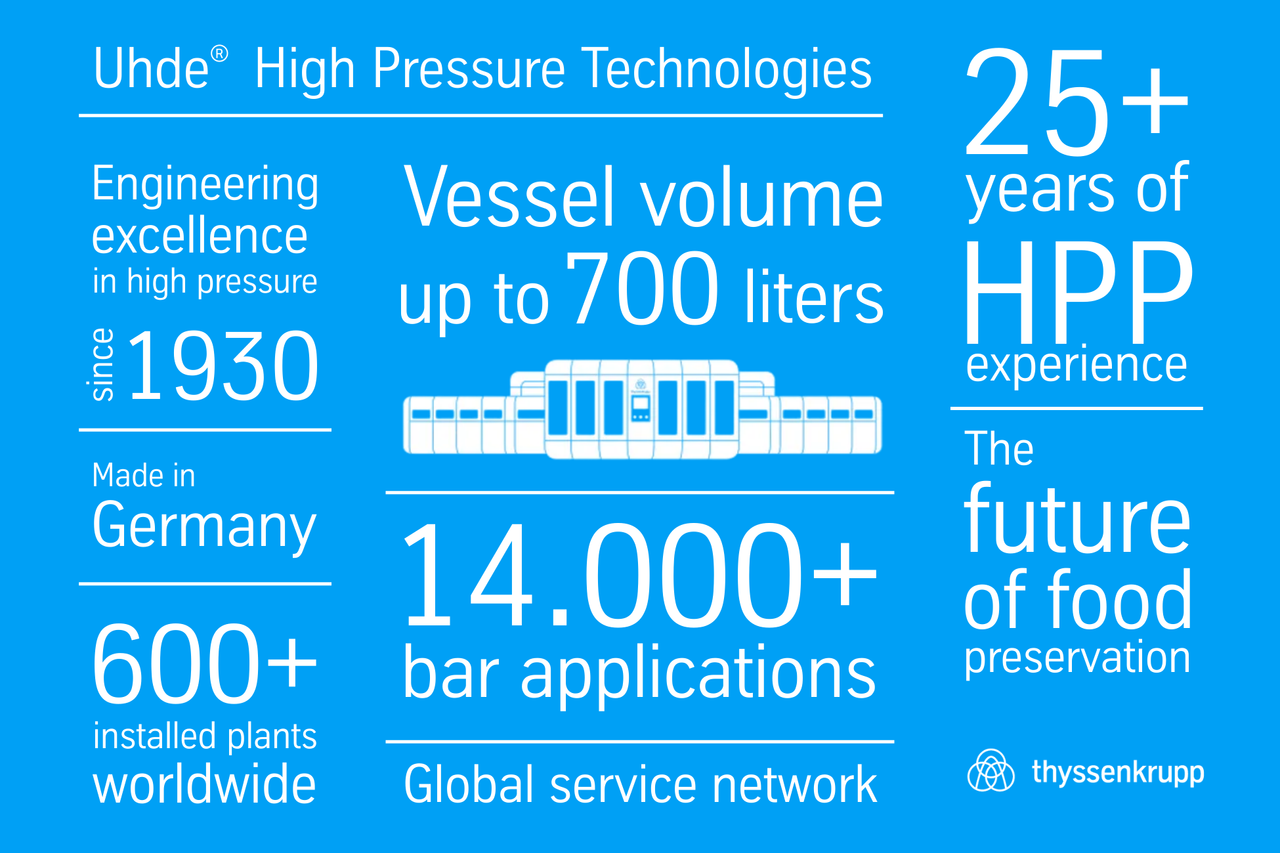

Uhde HPT is specialized in the construction of HPP plants and machinery. The Uhde High Pressure Technologies brand has stood for high-pressure excellence "made in Germany" since 1930. Our experienced team of engineers, chemists and technicians has been building tailor-made HPP high-pressure processing systems for more than 20 years. The machines are individually tailored to the high-pressure pasteurization of our customers.

Complete high-pressure processing solutions from a single source

Uhde High Pressure Technologies GmbH

Buschmuehlenstrasse 20

58093 Hagen

Germany

thyssenkrupp Uhde USA, LLC

11221 Cutten Rd, Bldg 5

Houston, TX 77066

USA

Uhde High Pressure Technologies GmbH

Buschmuehlenstrasse 20

58093 Hagen

Germany

Uhde High Pressure Technologies GmbH

Buschmuehlenstrasse 20

58093 Hagen

Germany

Get support from our High Pressure team

Have a question or need assistance? Provide your details and our team will be in touch as soon as possible.

Get in touch today!

/thyssenkrupp_logo_claim_d.svg)