High pressure processing offers you an opportunity to achieve the highest safety standards of premium and organic pet food so-called Biologically Appropriate Raw Food or BARF without losing essential nutrients for healthy canine nutrition.

Why is raw food important for a pet’s health?

In today’s society pets, especially dogs are often called a human’s best friend. However, this was not always the case. Measured by evolutionary standards, dogs were domesticated only 15,000 to 40,000 years ago. In the case of cats for example, this process took place about 10,000 years ago and thus even a bit later. Before that, these animals lived in the wild and were used to eat raw food.

People promoting the BARF (also known as Bones and raw food) diet defend the theory that such time is not sufficient for a pet to fully adapt to a new environment. They suggest this should be taken into account when it comes to a pet’s diet. Dogs for example are carnivores and their digestive system is adapted to processing of raw meat, different offal and bones at first place as well as elimination of the products thereof.

What are the benefits of BARF diet?

BARF is based on feeding pets according to their primal diet to ensure long and healthy life span. It has been suggested as an alternative to commercial diets to avoid the health risks of pets associated with cooked, preservative or grain-loaded pet food products that most of pet owners find convenient and inexpensive. The BARF diet consists mostly of raw meat, different offal and raw meaty bones (70–80%) which is combined with fruits and vegetables (20-30%). Carbohydrates are often eliminated or used in small amounts. For optimal nutrient supply many owners add oils and natural dietary supplements like eggshells, seaweed meal, and herbs.

The most important advantages of the BARF diet over feeding pets with dry food include:

Bones and raw food are easier to digest compared to commercial food that is often contains fibrous plants which hardly digested by both dogs and cats. It positively affects energy level, mood and demeanour of pets.

BARF products contain sufficient amount of essential nutrients for complete and balanced pet diet. Consequently, addition of minerals and vitamins is not needed.

BARF raw cat and dog food have a positive effect on the weight control of the pets. As many animals are overweight, and numerous conditions related to it, which can be prevented in the first place with BARF.

Chewing raw meat and bones helps dogs and cats to scrape off plaque off their teeth more than it is the case with a cooked diet. The chewing process benefits the circulation as well.

Being free of grain and gluten, BARF reduces the risk of allergic reactions. Commercial pet food containing wheat, soy or corn are more likely to cause such problems.

Nutrients present in BARF such as animal fat, B vitamins, amino acids, antioxidants and minerals are beneficial for the skin health and shiny hear of pets.

What are the risks of BARF diet?

Feeding raw food that did not go through high pressure processing poses a significant health risk to pets. Contamination with pathogen bacteria such as Enterobacteriaceae (Salmonella, E.coli, etc.) is more prevalent in BARF than in cooked pet food which poses large threat of infections. This accounts not only for the animals that eat the raw meals but also for humans who prepare the food and have direct contact with their pets.

With high pressure processing, these risks can be significantly reduced or even eliminated making raw diets for dogs and cats safe and healthy!

Particular attention should be paid to old animals, animals with weaken immune system due to various treatments or increased physical activities (i.e., racing horses or dogs). Mentioned animal groups can be extremely sensitive to microbiological contamination in their feed. Therefore, it is very important to provide those animal groups with clean and safe products rich in nutrients.

Why is HPP the benchmark for safe and tasty raw pet food?

The most important aspect of the high pressure processing is efficiency in elimination of common pathogen and spoilage microorganisms in BARF, which leads to increased product safety and shelf life.

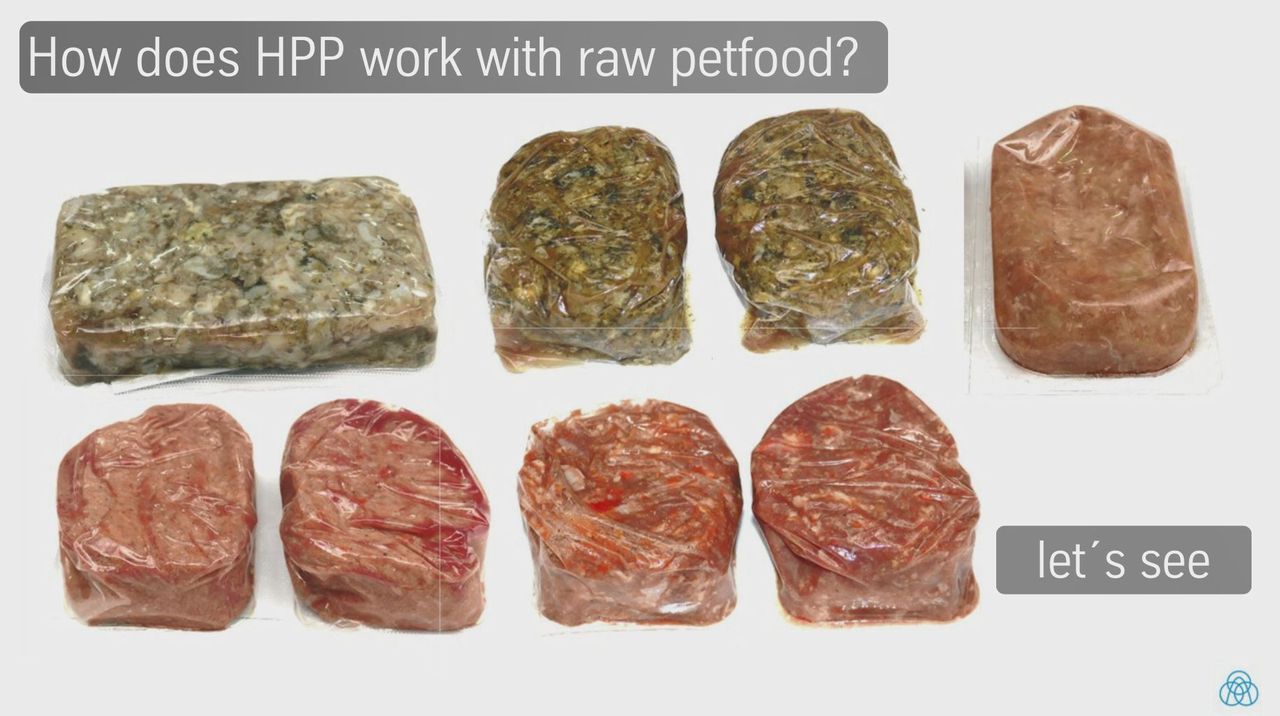

Preservation of BARF using high hydrostatic pressure excludes use of preservatives or chemicals. Almost no changes to the flavour, nutrients and natural appearance of the processed products occur. The original taste and aroma of the BARF is preserved with HPP. HPP is changing the colour of the meat from dark red to light red. For the pets the appearance is not as relevant as the taste.

Common BARF products are frozen and thus complicated for serving the pets the correct portion. The product should be melted an after melting it cannot serve again. BARF products preserved with HPP are only refrigerated and this makes it easier to prepare the correct quantity of each portion. After preparation the product can be closed and put back in the fridge for the next preparation. Beside of the preparation process also the storage is much easier during the logistic chain but also at customers site at home.

How does High Pressure Processing work?

Already in their final packaging, the products are subjected to high pressure in a water bath in a HPP plant. A water pressure of 6,000 bar is then applied to the foodstuffs, which eliminates bacteria and germs.

Click here to learn about our HPP Process in detail!

Sounds good? Check it out!

We’d love to demonstrate our high-pressure process on your product in our in-house test center.

/thyssenkrupp_logo_claim_d.svg)