What is High Pressure Processing (HPP)?

1. What is High Pressure Processing (HPP)?

High pressure processing allows gentle preservation of food by high pressure without additives or heat. To achieve this a pressure of 6,000 bar – which equals roughly the weight of three jumbo jets acting on a smartphone-sized area - is applied to the products. The food is conveyed in special baskets into a high-pressure vessel. It then moves into the machine and is filled with water. Pumps increase the pressure in the vessel, which is applied both immediately and evenly spread leaving no evident crushing effect on the products. Once finished the pressure is reduced and your product has a much longer shelf life and maximum product safety.

2. How does High Pressure Processing work?

Products in flexible and water-proof package are conveyed within the plastic baskets into a high-pressure vessel. Water is filled into the HPP vessel and pressurized to pressure of 6,000 bar. Acting instantaneously and uniformly through a mass of a food or independently of the size, geometry and composition, isostatic pressure leaves no evident crushing effect on the products.

High isostatic pressure inactivates food-borne microorganisms and spoilage enzymes in a few minutes, while minimizing the loss of food quality. Upon high pressure treatment the vessel is depressurized and water is drained. Products in baskets are conveyed out of vessel and are ready to consume!

3. How does High Pressure Processing preserve food?

Since high pressure eliminates many food-damaging organisms and can deactivate microorganisms, decay processes are significantly slowed down and in some cases even prevented. For example, some types of fruit no longer turn brown. Flavors and vitamins, on the other hand, consist of very small molecules and do not belong to the group of weak bonds. They are not damaged and remain intact.

High pressure processing has proved particularly effective for fruit products and meat products. Although even very sensitive foods in their final packaging are exposed to this pressure, their appearance and consistency remain unchanged after treatment.

4. Is HPP safe for pregnancy?

HPP food is safe and recommended for pregnant women!

Food-born pathogen Listeria monocytogenes that can cause a condition called listeriosis is 20 times more likely to sicken pregnant women and their newborns, adults older then and people with weakened immune system. Listeriosis can lead to miscarriage or premature birth and diseases of internal organs, skin diseases, respiratory problems and spasms of newborns. Listeria can be found in raw meat or fish, vegetables that are contaminated from fertilizer, and unpasteurized dairy products and ready to eat meals.

HPP at 6,000 bar for only 5 min reduces listeria to below the detection level and inhibits its growth during storage of food. At the same time, food retains fresh-taste and all key nutrients for a healthy pregnancy.

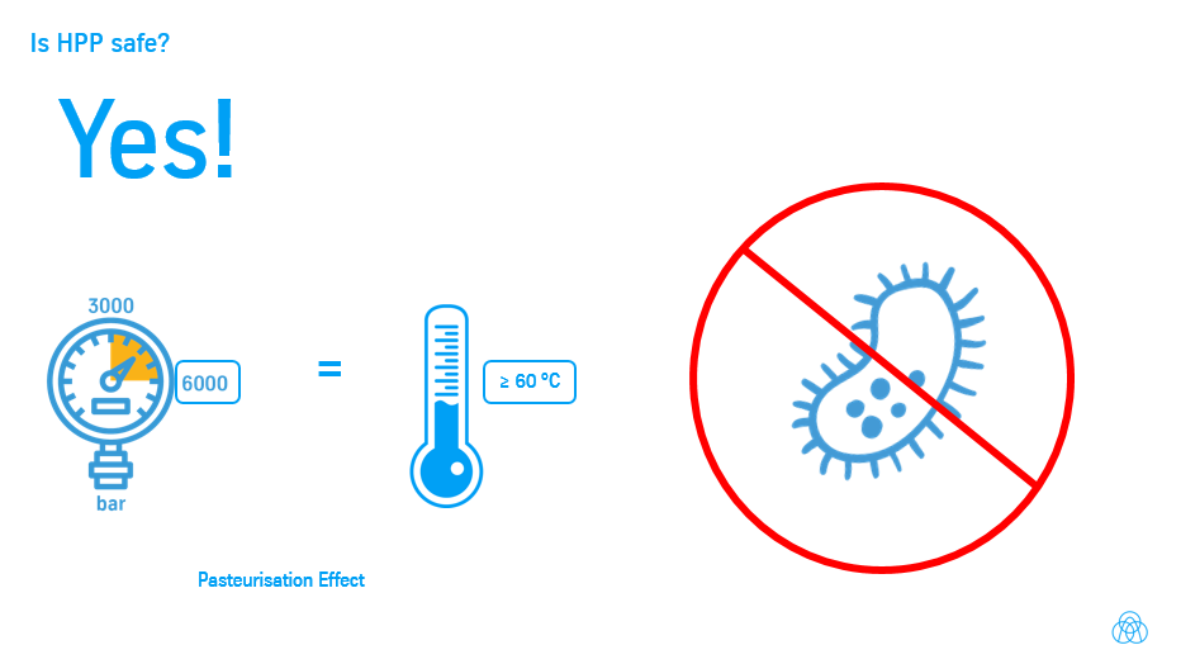

5. Is HPP safe?

When it comes to food preservation there isn’t anything safer!

The conservation of food has been on people's minds for thousands of years. Humans have developed countless methods and techniques to preserve their food, to make germs and bacteria harmless or to preserve the taste and vitamins.

While ancient techniques such as smoking and curing made it possible to increase the shelf life of food, numerous unintended side effects had to be tolerated: It could not be assumed with certainty that the food was germ-free and fresh, and contaminations frequently occurred as well.

High Pressure Processing is the method that eliminates all these disadvantages. While unwanted microorganisms can survive even under conditions of extreme heat or cold, germs and bacteria are susceptible to changing pressure conditions and can be eliminated by applying pressure.

The result: much longer shelf life and maximum product safety and therefore more satisfied customers.

6. How does pressure inactivate bacteria?

HPP compromises cellular functions such as DNA replication, transcription, translation already at lower pressures (≤100 MPa) which impairs bacterial growth.

At higher pressures, microorganisms start suffering lethal injuries due to loss of cell membrane integrity and protein functionality. The most sensitive to pressures are molds, yeast and parasites. Inactivation of common bacteria requires higher pressure (300-600 MPa). The most barosensitive are bacterial spores that were found to survive pressures up to 1200 MPa at room temperature.

7. When was High Pressure Processing invented?

The conservation of food has been a concern of people for thousands of years. Humans have developed countless methods and techniques to preserve their food, to make germs and bacteria harmless or to preserve the taste and vitamins.

Methods such as curing and smoking were early techniques to extend the shelf life of food but came with unintended side effects such as contaminations, which occurred frequently.

This changed in June 1899 when Bert Holmes Hite (1866-1921), a researcher from the University of West Virginia (USA), had demonstrated the inactivation of microorganisms using high hydrostatic pressure for the first time. This was the first document on pressure being used as a food preservation method. An intensive research on HPP followed, which led to design and manufacturing of first commercial units in the early 1990’s. It started with fruit jams in Japan and soon after HPP orange juice was offered in French supermarkets. From then on, number of HPP applications has been steadily increased-from preservation to structural alteration of food and production of added-value food.

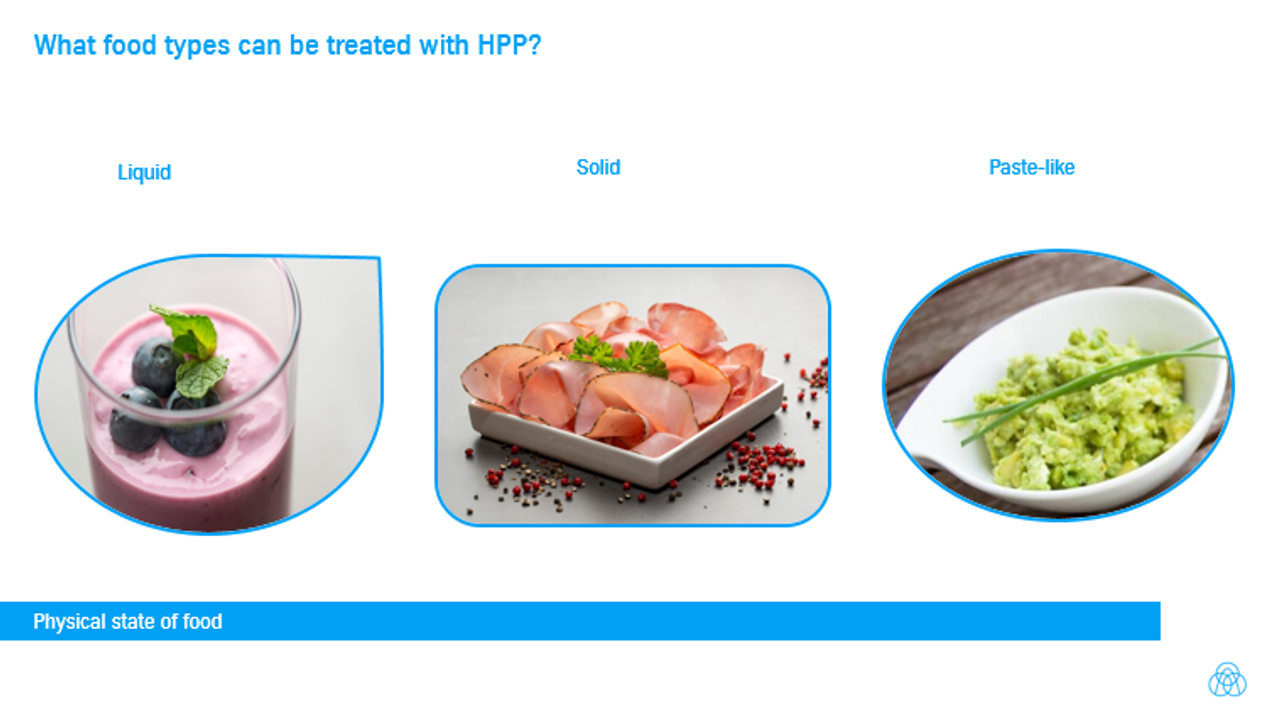

8. What food types can be treated with HPP?

A variety of high moisture foods can be preserved using HPP including solid, liquid or semi-liquid products. In general, minimum moisture content of 40% is suggested for effective microbial inactivation.

Suitable for HPP preservation are:

low-medium moisture, semisolid or solid foods packed under vacuum (sausages, dry-cured, cooked meat products, cheeses, seafood, marinated products, RTE, dips, sauces)

high moisture solid foods in plastic cups or pouches (fruits jams, marmalades, compotes, purées)

high moisture liquid foods in plastic bottles (dairy products, fruit and vegetable juices, bioactive beverages).

Foods with entrapped air (bread, cakes, mousses, strawberries, marshmallows, leafy vegetables) or with insufficient low moisture content (powders, dried fruits, spices) will be crushed or compacted under high pressure.

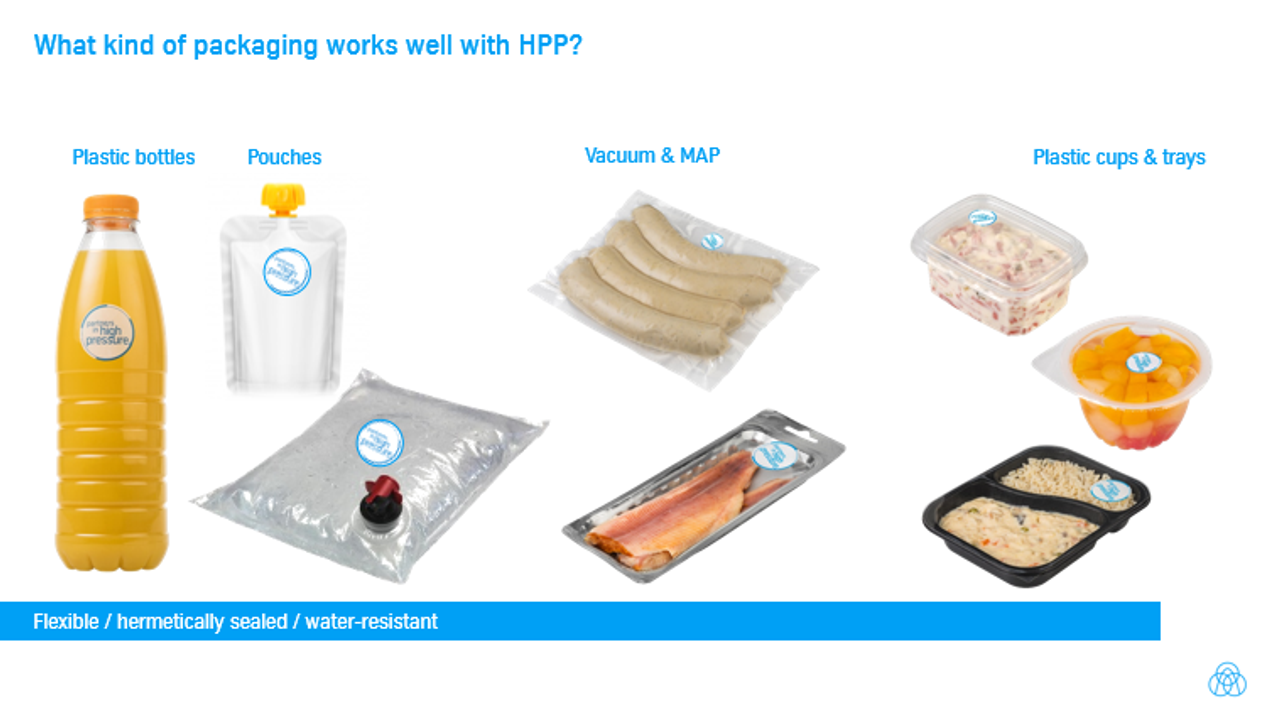

9. What kind of packaging works well with HPP?

Under high pressure of 6000bar the product and packaging undergo a temporary volumetric reduction of 15%, which is reversed upon depressurization. Packaging for HPP must have sufficient elasticity, at least in one side, to transmit pressure and accommodate up to 19% volume reduction without losing seal integrity or barrier properties.

Plastic bottles, pouches, cups, and trays made of PET, PE, PP and EVOH (or combinations thereof) work very well with HPP due to their good water barrier properties and flexibility. Glass, metal, rigid plastic containers, plasticized cardboard carton packages undergo irreversible deformation or tend to fracture under compression.

Vacuum and modified atmosphere packaging (MAP) work very well with HPP. If labelling is required prior HPP, shrink sleeve and in-mold labelling or indirect relief printing are suitable labelling technologies. PE and PP labels combined with flexographic and digital offset printing can work with HPP.

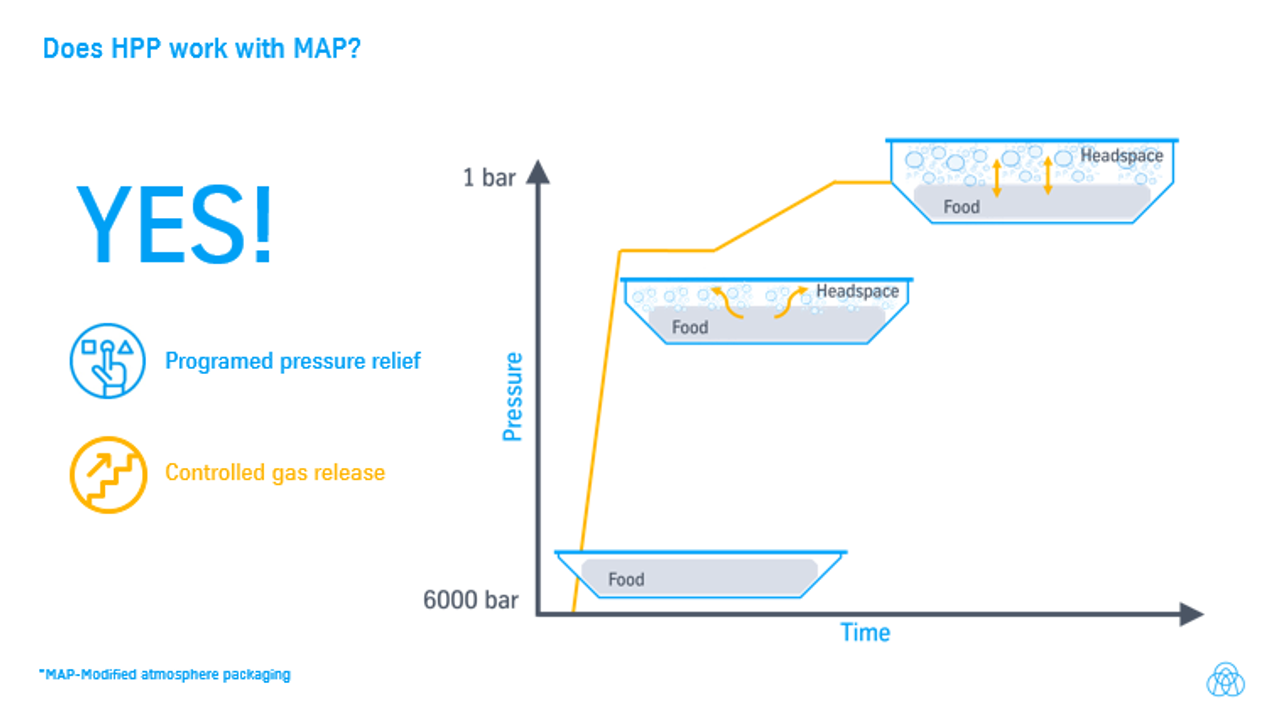

10. Does HPP work with modified atmosphere packaging (MAP)?

Modified atmosphere packaging (MAP) keeps the fresh-like appearance and extends shelf life of the products. Suitable gas mixtures, typically CO2 and N2 or O2 are used to evacuate air and adjust oxygen level in the packaging according to the product requirements prior sealing. Using MAP with HPP is possible and can be beneficial for shelf life extension.

Gaseous headspace (30-50%) in MAP leads to a higher volumetric reduction under high pressure compared to the vacuum packaging. Under high pressure molecules of inert gases are sporadically absorbed by packaging foil. A rapid pressure release after the high pressure treatment results in a sudden volume increase of the gas molecules. Upon fast gas expansion, resulting mechanical load on the product-side layers of the packaging foils causes local micro-defects which impair appearance and functional features of the packaging.

Our HPP technology enables controlled and gentle gas release to ensure both packaging integrity with product safety.

11. How does High Pressure Processing (HPP) affect shelf life?

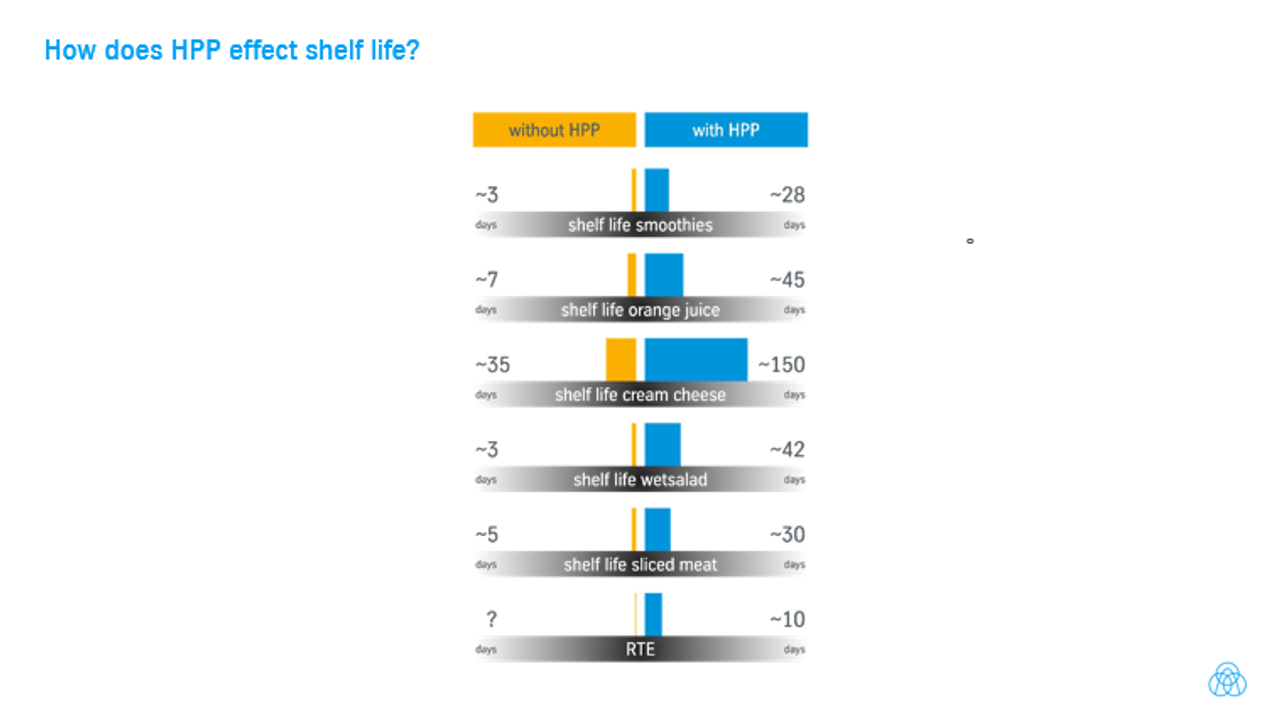

HPP effect on shelf life extension depends on process and product parameters. High pressure and longer holding time generally favour microbial inactivation and decrease of enzyme activity. Water activity, pH value, fat or carbohydrate content can affect barsoresistancy of the microorganisms.

Therefore, HPP effect on inactivation of the same microorganism can vary from product to product. Storage temperature after HPP is also the factor that can influence shelf life of the product. HPP can increase shelf life to 10 times in comparison to non-treated fresh products.

In industrial practice the pressure level and holding time are optimised to ensure maxium safety without impairing the organoleptical and functional properties of the product.

12. How long does a HPP cycle take?

Commercial HPP is carried out as a batch process. Typical holding time is 3 to 5 min depending on product to be preserved. Pressure building up depends on pump system used and target pressure for the product´s treatment.iFor commercial applications moderately high pressures of approx. 3000bar is used for shucking of oysters or extraction of crustacean meat and 6000bar is used for preservation and shelf life extension of foods. Higher number of pumps and treatment at lower pressure favour faster pressure build up. Depressurisation rate usually takes few seconds unless other conditions are requested, e.g. in the case of high pressure treatment of MAP or life science applications.

For commercial purposes and evaluation of output, it is necessary to take into consideration time for loading and unloading of the product. Automation level of filling the products into the perforated baskets and unloading thereof will greatly effect productivity and production costs.

13. Which filling degree works with HPP?

Filling degree of the high pressure vessel is one of the key factors that determine the output and processing costs.

Higher filling degrees can be achieved by using a proper packaging design which includes dimensions, form and type of packaging (MAP, vacuum, PET bottles). Higher filling ration is achieved by using packages with higher volume or bottles with square or hexagonal profile. Having a 30-50% of headspace, MAP packs occupy a higher volume in the vessel compared to vacuum packs, which means lower filling degrees. Flexibility of packaging, i.e. using pouches vs. cups can also improve packing efficiency.

14. What are the key advantages of HPP?

Products are treated in their final packaging which minimizes risk of recontamination from any step of production chain.

Hydrostatic pressure acts instantaneously and uniformly throughout the product. It provides gentle and at the same time thoughtful food treatment. No heat is used, so that nutrients, bioactive ingredients and flavour of food are retained.

HPP efficiently inactivate harmful microorganisms and enzymes leading up to 10 times longer shelf life. It minimizes risk of costly recalls and helps faster business growth. Longer shelf life of fresh food facilities its distribution and reduces food wastage in the supply chain.

HPP can increase productivity, improve appearance and add value to the products (bivalves shucking). High pressure alters structure of proteins and hydrocolloids helping to create new products or to improve food texture, functionality and therapeutic properties of the products.

Use of HPP excludes preservatives bringing out clean label products.

/thyssenkrupp_logo_claim_d.svg)