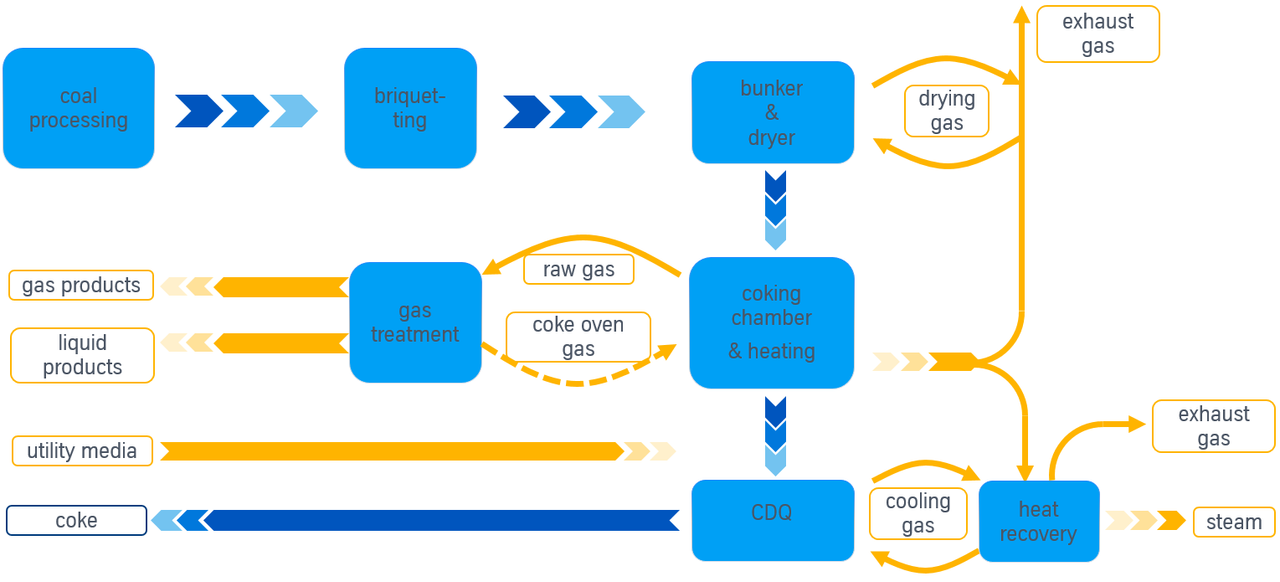

Vertical coke ovens are universal units for the pyrolysis of a diverse range of different feedstocks.

Even low-grade feedstocks such as bituminous coal, lean coal, gas coal, flame coal, lignite, anthracite or biomass can be used.

However, while low-grade coal is easy to mine, it is difficult to convert into coke. Therefore, the technology requires sophisticated, well-selected, skillful coal preparation.

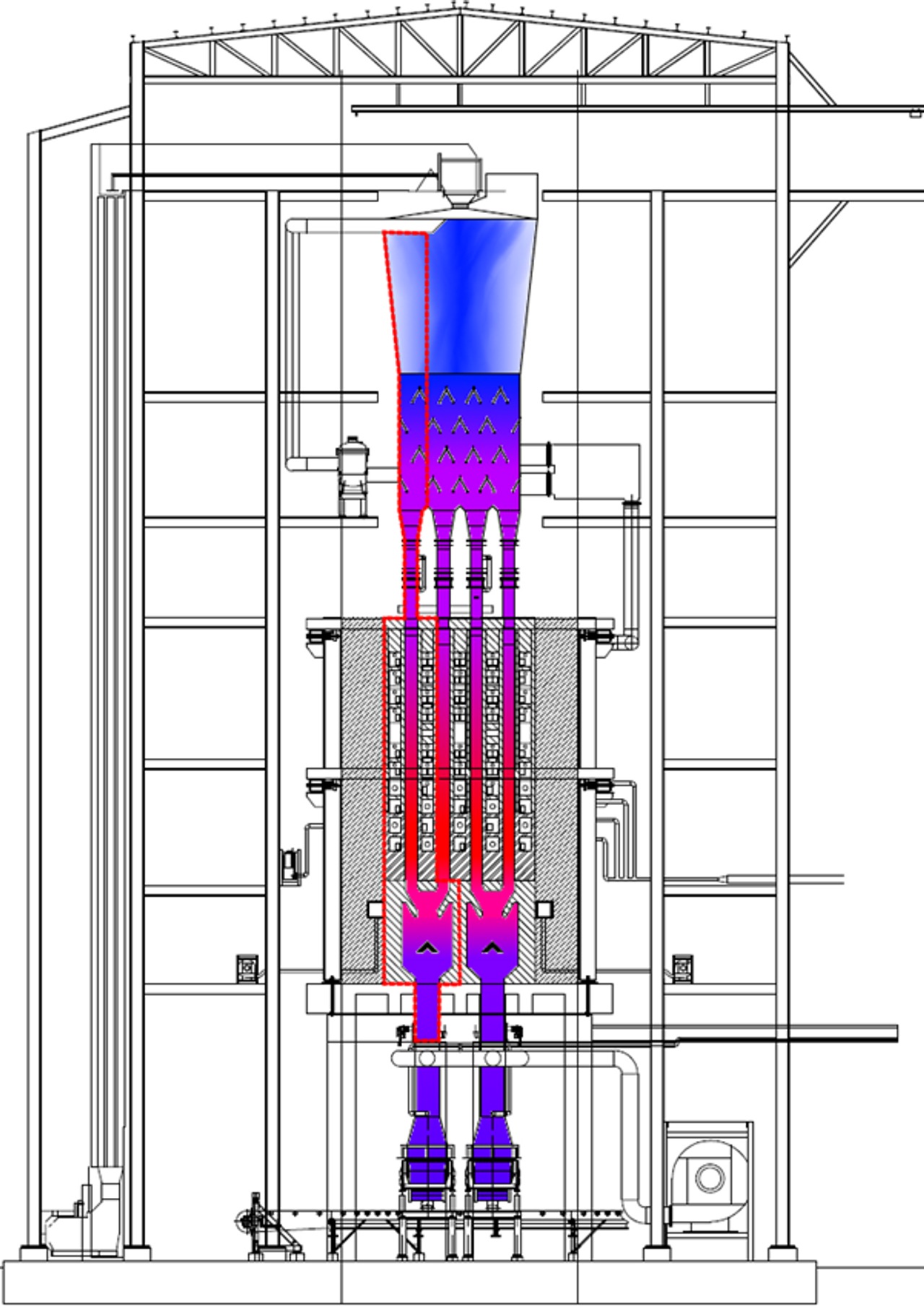

The refractory block consists of up to eight coking chambers separated from the corresponding heating walls by liner bricks, thus ensuring indirect heating of the briquettes by combustion processes in the adjacent heating flues.

The heating flues are arranged in a meandering pattern. This arrangement makes it possible to achieve a specific vertical temperature regime that follows a carefully maintained temperature curve, which is tailored to each coal blend in the run-up to a project.

The coke is quenched in a coke dry quenching unit (CDQ) located below the coke oven chamber.

Use of the gases generated

The resulting flue gas can be used as a drying agent in the upper drying unit. The resulting raw gas streams are collected in a number of gas collecting mains at different heights. This results in the separation of the various by-products, which are further processed into valuable chemicals in downstream processes. Such valuable chemicals include olefins, phenol, methanol, dimethyl ether, synthetic natural gas, humic or formic acids.

/thyssenkrupp_logo_claim_d.svg)